How We Powder Coat Metal Signs and Fire Pits

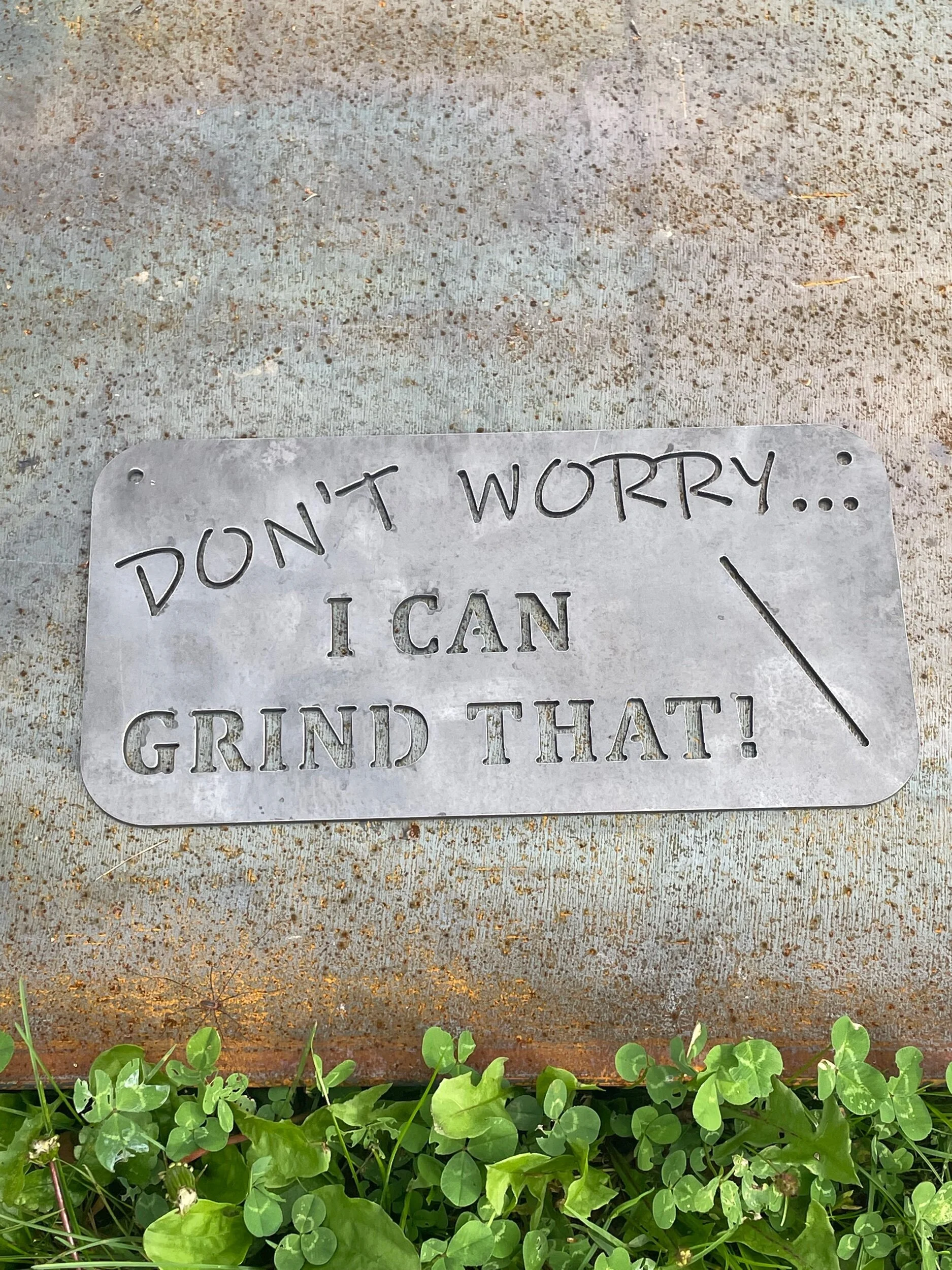

Here at Chiasson Smoke, we take pride in building metal signs and fire pits that look as good as they perform. A big part of that quality comes from our in house powder coating setup, which allows us to control every step of the finishing process and deliver durable, professional results every time.

Our powder coating process starts with surface prep. Before any color is applied, each metal sign or fire pit component needs to be perfectly clean. For that, we use a blast cabinet that removes dirt, mill scale, and surface imperfections. We upgraded the cabinet by removing the original siphon system and pairing it with a Harbor Freight blast pot. This setup gives us consistent blasting power and helps ensure the powder coat sticks the way it should. Smaller parts and signs are prepped right here, while oversized pieces are blasted at our other shop so nothing gets rushed or skipped.

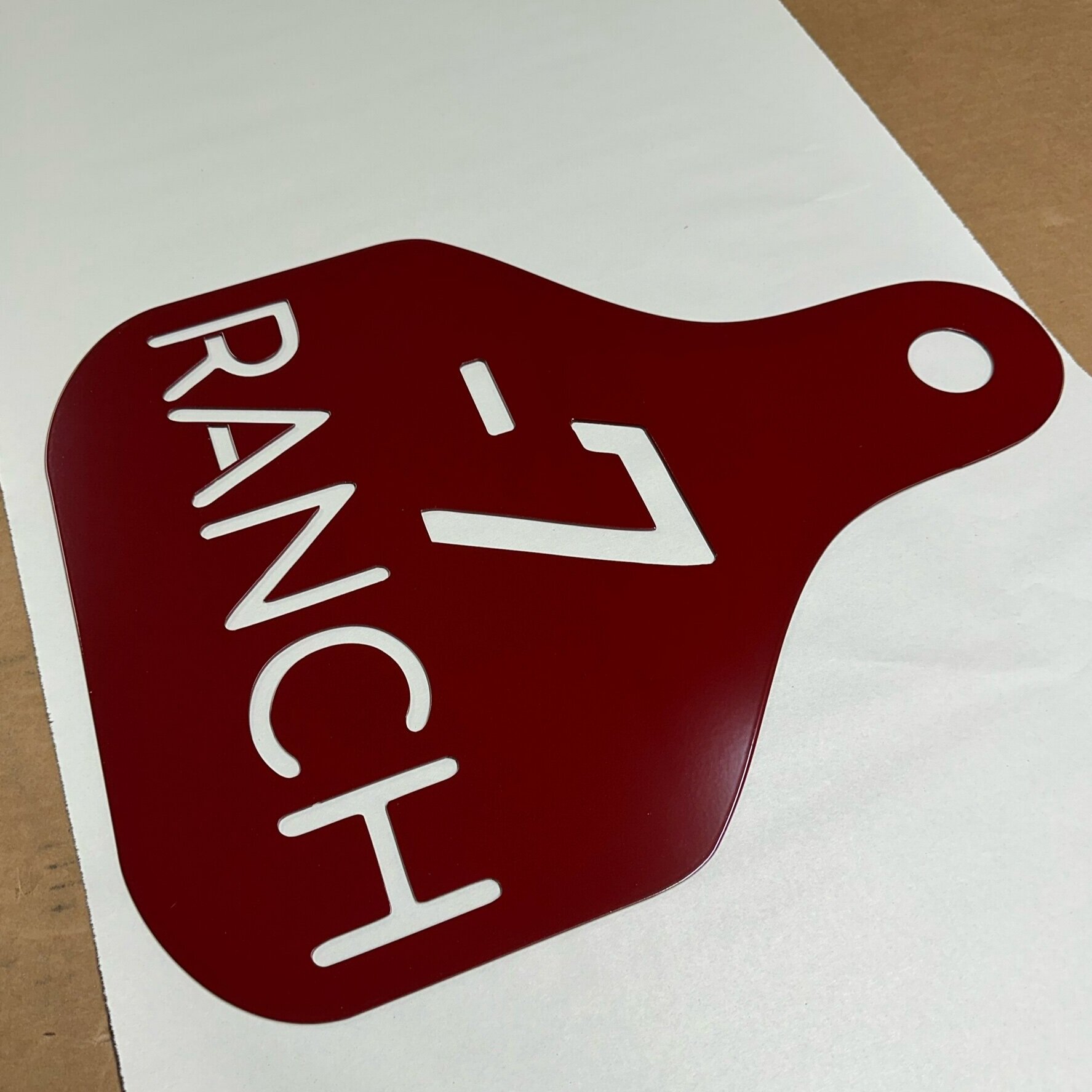

Once the metal is clean, it is ready for color. We keep a wide assortment of powder colors in stock, which lets us move quickly on custom orders without waiting on materials. Whether a customer wants a bold, eye catching sign or a clean, classic finish, we already have what we need on hand. As signs are coated, they move through the shop daily, flowing from prep to coating to packaging with an efficient system that keeps orders moving.

Clean, dry air is critical for powder coating, and our air system is built for that job. We run a Max Air 16 bar screw compressor with built in filtration and a refrigerated dryer. This setup delivers extremely dry air, which helps the powder spray evenly and keeps defects out of the final finish. It is one of those behind the scenes details that makes a big difference in the final product.

For curing, we use a dedicated powder coating oven that is sized perfectly for our signs and fire pit components. The oven heats the coated metal evenly, allowing the powder to melt, flow, and harden into a tough, protective finish. This step is what gives powder coating its well known durability, making it resistant to chips, scratches, and weather.

The heart of our coating process is the spray booth and powder gun system. We use an Electron powder coating system that we originally purchased at Fabtech a few years ago, and it is still going strong today. It applies powder smoothly and consistently, helping us achieve clean edges and even coverage on every piece.

This powder coating setup allows Chiasson Smoke to maintain tight quality control from start to finish. By handling everything in house, we can ensure that every metal sign and fire pit not only looks great but is built to last.